New World Dutch Barn Frames For Sale

Whether you are looking for a beautiful working barn, a quaint cabin, a majestic great room, a one of a kind estate, or simply a peaceful home, filled with the charm found only in vintage timber frame homes.

Each of these historic structures represent unique piece of history. These antique hand hewn barns are the fruit of searches across both North American and Canadian farms. We look forward to hearing from you so we can help make your dream a reality.

Click the buttons below to sort our available frames

NEW WORLD DUTCH BARNS

1462 Palatine Dutch

52 x 60

1442 Gunnerson

38 x 52

1441 Copperknoll

39 x 50

1430 Newry

75 x 55

1415 Berne

45 x 50

How we restore timber frames

Our process for restoring timber frames has been trialed and tested for years, so we know exactly how to treat your barn parts so they look as good as they were when they were first constructed. Take a look at our process to understand better how our timber frame restoration projects work.

1. Delivery

The first step of every project involves the transportation of your original beams and barn parts. We label all the parts and safely deliver them to the restoration yard, where they’ll be restored and repaired by our team of restoration experts.

2. Repair & Restoration

After the safe arrival of your parts, our team will repair and restore your barn using wood that matches the barn in species, color, and texture. Then we use original hand tools to create an authentic finish.

3. De-Nailing, Cleaning & Fumigation

From here, our team will remove nails in the frame and carefully wash and clean the parts. Then it’s on to one of the most important steps in restoration - fumigation. This eliminates any small bugs, which can be a serious problem if untreated.

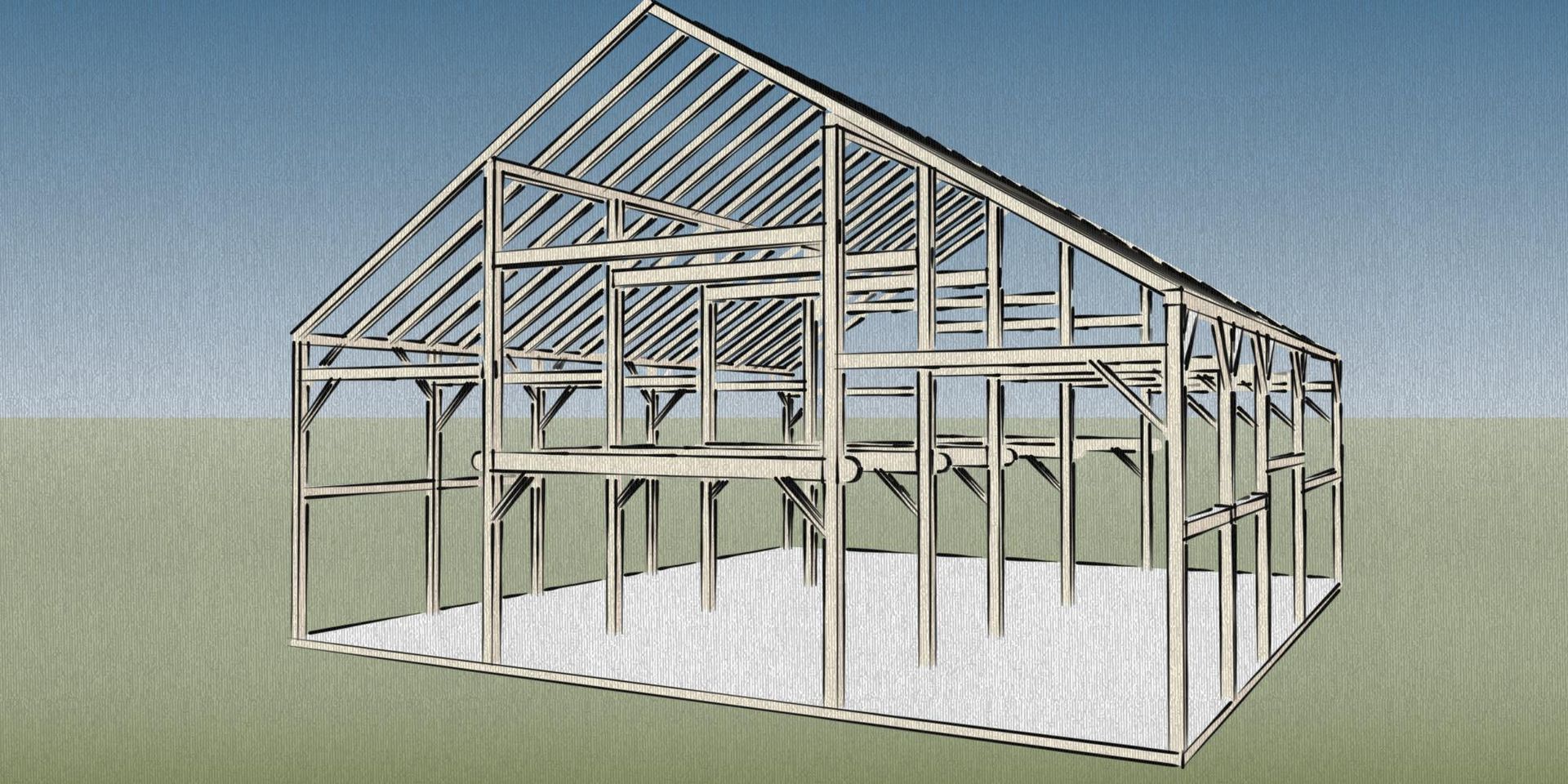

4. Scaled Drawings

After your barn parts and beams have been restored and fumigated, we’ll draw up accurate drawings to help with the rebuild. We’ll provide you with an architect who will draw up your barn’s design to save time when it comes to constructing the frame again.

5. Delivery & Build

After carefully transporting your barn frames to the construction site, our experienced crew will skillfully erect your historic timber frame quickly and efficiently.

6. Support & Follow-Up

Once the frame is erected, you, your architect, or your contractor can call us anytime during the renovation to ask questions about restoring heritage barns. Alternatively, we’d be happy to take on a full restoration project for you.

FREQUENTLY ASKED QUESTIONS

You probably have many questions about how to transform a barn into a home or other buildings.

We’ve compiled the following questions and answers to help you understand the process.

-

What Is Included In The Price Of One Of Your Barns?

Unlike barn frames that are sold directly off of the site, our prices are comprehensive and include:

1 – Delivery from the original location.

Transportation of the beams and all the barn parts includes labeling all the parts and getting them safely to the restoration yard.

2 – Repair and restoration.

We repair and restore our barns using original wood that matches the barn in species, color and texture, using original hand tools to create an authentic finish.

3 – Are these beams used for repairs an extra charge?

Our price includes all the beams needed for repairs.

4 – De-nailing, washing and cleaning.

Every frame needs removal of nails along with careful washing and cleaning.

5 – Fumigation

This is one of the most important steps in restoration. Small bugs make for big problems if they go untreated.

6 – Scaled drawings.

These are necessary for an accurate restoration and rebuild. We can provide your architect or builder with CAD drawings and save them lots of time in measuring and planning.

7 – Delivery to the building site.

Barn frames are heavy and dangerous to move. We provide all the heavy equipment for this process.

8 – Crew and equipment to stand the frame on location.

Our experienced crew works safely and efficiently to get your historic timber frame erected in a timely way.

9 – Insurance

There can be legal complications if you purchase a barn that is standing, and then the middleman/seller has the barn taken down by a crew that is not insured. If a worker is injured, he will likely go after you as the owner of the barn for compensation. WE ARE FULLY INSURED.

10 – Support and follow-up

We have completed over 300 barn home projects and you, your architect or your contractor can call on us at any point along the way to ask questions about how to do or where to get something.

We also offer all kinds of additional antique materials to go with our barns, (which are priced as extras) including extra beams, rustic barn siding in various colors and aging, and barn flooring.

-

Do You Travel To Other States?

Yes. We will restore and relocate these historic buildings anywhere in the world.

-

Why Buy A Historic Barn Frame & Not A New Timber Frame?

Our antique timber-framed homes have timeless character that cannot be duplicated in a home built with new wood. The materials speak of a past in which craftsmanship and enduring quality went hand-in-hand. The hand-hewn structural timbers were cut from the early American virgin forests and are much larger than any timbers available today. These time-tested, hand-crafted structures are then finished with modern, innovative, energy-efficient designs and materials. The completed structures make beautiful and unique homes, guest houses, commercial spaces, event venues, and even…barns!

-

Is It Possible To Convert An Existing Barn Into A Home On-Site Without Dismantling & Restoring It?

We are often asked about the possibility of restoring a barn on site. This has been done, but such a project poses some real challenges:

1- The Foundation

Existing barns are most often built on dry-laid foundations, that is, stone foundations without mortar. They have shifted over time and will always be a source of extensive maintenance. Such a dry-laid foundation is also not weather-proof, allowing for cold and damp air to freely circulate under your finished home. You can jack up the barn and build a new foundation under it, but this in itself is an expensive process that makes taking down the barn more feasible.

2 – The Beams

The purpose most people build a barn home is to see the ancient beams. If you try to insulate an existing barn from the inside to make it a home, you will have to cover over much of the beams. The only way around this is to attach your insulation onto the outside walls. But then you don’t have a foundation to support this insulated wall as you’ve built a building larger than the dimensions of your foundation.

3 – Bugs

Barns have to be fumigated to become homes. They often have some pernicious pests in the wood that you will not notice until your home is completed, when it is too late to cost-effectively treat them. We fumigate all of our frames while they are disassembled. On the other hand, the process of fumigating an entire barn in place involves putting a tent over the entire structure and posting a guard on site while the fumigation process takes place. This expense alone can be upward of $30,000.

Considering the above, we do not recommend investing the time and money into such an undertaking. It is simply not a good investment.

-

How Old Are Your Barns?

Our barns range in age from 125 to more than 250 years old. Many pre-date the American Revolution of 1776.

-

How Do You Know The Age Of These Barn Frames?

Watch our video explanation here!

-

Will My Finished Home Smell Like A Barn?

All of our barns are completely washed and fumigated during restoration. We have never had a problem with residual odors.

-

Are There Different Types Of Barns?

One of the wonderful things about these barns is that no two are the same. While each frame follows one of several basic traditional designs, the variations in a barn’s overall size, species of wood, girth of the timbers, etc. are as diverse and unique as the farmers who used them, the craftsmen who built them, and the resources of the region in which they were built.

-

What Is The Resale Value Of A Barn Home? If I Decide To Sell My Barn Home Someday, Will A Unique Home Like This Appeal To A Large Segment Of Home Buyers?

Barn homes are now widely regarded in construction and design magazines. Architectural Digest regularly runs articles featuring restored barn homes, and other articles featuring barn homes appear continually in publications as diverse as Country Living, Victorian Homes and Timber Homes Illustrated. Barn homes have also been regularly featured on programs such as “This Old House.” The uniqueness, rustic beauty and timeless craftsmanship of restored, historic timber-frames appeal to a very wide cross-section of custom home buyers and therefor enhance their resale value.

Of the more than 300 barn homes we have built, very few have been on the market because the owners are as in love with them. The few that have been offered for sale sold readily.

-

Is It Hard To Design A Home Using A Barn?

Unlimited options are available in designing your barn home. You can use one barn or several, add lofts, and even use conventional framing to make additions to the barn frame. Please take a look at our finished projects on the Barn Showcase pages to view some interesting and creative variations.

-

Do You Offer Design Services?

Step 1: Select your timber frame

Each barn in our inventory has a unique history, size and look. Our timber-framing crew includes experienced craftsman skilled at modifying timber frames. While the restoration process allows much flexibility, a selected frame introduces certain givens for how we are going to approach the overall design. For instance, there might be specific markings on the frame we want to showcase or specific timbers that should frame a key space.

On the other hand, your general design might be more flexible and your barn selection driven by the history behind the frame, where it was found, or what species of wood the beams are. So, we have found that selecting the right frame is the best place to start the process.

As we become engaged in the many facets of the building you want to complete, we can begin making frame recommendations, while advising you of a particular frame’s, history, origin, and modification options.

Step 2: Program your Building

Once a timber frame is selected our design team meets with you to consider your space needs, space relationships, the unique frame features, and modification options. Sometimes the complete design may be fully contained inside the limits of your historic frame. Other times we’ll incorporate a number of conventionally framed additions into the design to offer additional spaces the frame on its own doesn’t accommodate. This step defines the over-all exterior form of the building early in the process. Your involvement is critical and guides us in reaching design solutions that ultimately meet your needs.

Step 3: Material Selection

In custom architecture, available materials have seemly endless options. So, we try to determine at a performance level the exterior materials as they affect important structural and architectural construction assemblies. We produce exterior renderings of your building to help visualize the final product as part of our standard design process.

As we wrap up the design phase of the project, the building must harmonize architecturally, structurally, mechanically, and environmentally as well as it looks.

We develop final construction drawings as you solidify materials selections and approve the final building form.

Step 4: Building your Development

As a General Contractor, your design team is feeding you current construction pricing through-out the design process, so you’re equipped to make educated design decisions effectively avoiding a budget crisis at any point in the design or construction phases. Key areas of interest are pre-determined in order to offer appropriate budgets to the areas most important to you.

Our construction team works inside the budget and offers weekly updates in cost and work progress through an interactive area of our website that allows you convenient access to current pictures, drawings, contracts, and costs; and gives you the control to allow access to family and friends as momentum builds to see your project come to final completion.

-

How Long Does It Take To Build A Barn Home?

After the foundation is prepared, we can deliver and erect your barn frame in one week. Once the frame is erected, the finish out will take no longer than any other custom home.

-

Do You Build The Complete Home?

Yes. We can supply the historic timber frame, restored and re-erected on your building site. We can also provide custom millwork such as doors, flooring and staircases, as well as antique materials. And we can general contract the entire finish out of homes.

-

When I Purchase A Barn Home From You, Are You Available To Help Me Through The Process, Even If You Do Not Do The General Contracting?

We stay with you throughout the process and are always available to you, your contractor and your architect.

-

What Are The Steps In Building A Barn Home?

Building a barn home is not a mystery. To give you an idea of what it takes, we will walk you through a typical process.

1 – Initial Contact

Call our office and let us know your ideas. What size home. How many bedrooms and baths, etc.

2 – Plans

You may have a floor plan for your house in mind or you may need to look at plans. We can show you plans that you can modify to your likes or we can help you come up with an entirely new plan. Instead of working with our design team, you may already have plans or want to enlist another architect to help you. We will gladly work with your plans or any architect you choose to work with.

3 – General Contractor

Our barn frame sales contract includes our standing the historic frame on your foundation. To complete the construction, you may have a general contractor, or, depending on where the project is located, we also have a general contracting company capable of completing all the construction on your home.

4 – Once you have a plan, you can determine which barn will work and whether you want to go ahead with purchasing a barn frame.

5 – Depending on your locale, you may need to go through a permit process with the local town. We have never had a problem with this permitting process that prevented the buildings from being built. Even though building a barn home is unique, it is universally accepted.

6 – You have your land and your builder and your barn frame and you are ready to begin. First, the site needs to be cleared and the foundation installed.

7 – The barn frame may already be restored and stored in our yard, or we may be in the process of taking it down. Preparation of the barn frame is not a delaying factor in most all of our barn projects. We have an experienced crew that is able to meet deadlines. It is also at this time that any alterations to the frame are done to customize it to your plan.

8 – Once the foundation is ready, we arrive with the barn frame. (Now it gets exciting.) In under a week our crew will have your barn frame erected. It is now ready for the walls and roof to be framed.

9 – Then you will go through the rest of the process of building, not unlike any other house:

Sheathing, roofing, exterior siding, plumbing and electrical, heating and air conditioning, interior finishes, cabinetry, flooring, painting, installing fixtures.

And then you move in and realize that it really is a wonderful, unique house. Everyone will marvel at it. You will become a revered historian and local legend. And you will sleep better at night with the thought that some time, hundreds of years ago, perhaps even before Thomas Jefferson sat down and wrote the Declaration of Independence or Washington and his small army crossed the Delaware, or Davy Crockett and his Tennessee Volunteers died defending the Alamo, some pioneers built your home’s frame by hand with the broad axe and adz from the wild, virgin forest. And they never imagined in their wildest dreams that one day you would be living in it...and neither did you.

-

What Type Of Foundation Is Best For A Barn Home?

We have built barn homes on concrete slabs, on pier and beams with wood-framed floors, and on full basements. You can finish the floors in anything you like, including carpet, tile, wood or stained concrete.

-

What Are SIPs?

Structural Insulated Panels, or SIPs, are a cost-competitive, highly energy-efficient and labor-saving way to enclose an historic timber frame, and have been used in new construction for decades. They are basically pre-fabricated, panelized walls, replacing in one step: framing, sheathing, and insulation.

-

Do You Have To Use SIPs To Enclose The Timber Frame?

No, we typically use conventional 2×6 framing around the timbers and insulate with spray foam or fiberglass or other insulation.

-

Does A Timber-Frame Home Limit The Type Of Interior & Exterior Finishes I Can Use?

Not at all. You can use any type of roofing, siding, and interior finishes available for conventionally constructed buildings. We have finished timber frames with roofs of metal, slate, cedar shake, tile, copper, thatch and asphalt shingles. Exterior siding can be stone, wood, stucco, brick or any combination of materials. Interior finishes also can be anything from textured and painted drywall to stone and antique barn wood.

-

How Does The Energy Efficiency Of A Frame Wrapped With SIPs Or Spray-Foamed Compare To Conventional Construction?

SIPs and spray foam have several energy-saving advantages over standard construction methods. Their R values are at least 30-40% higher than fiberglass insulation of the same thickness, but this is only half the story. Their greatest energy-saving advantage over conventional framing and insulating is they create a seamless, insulated envelope around the timber frame.

-

How Are Electrical Wires & Plumbing Run In SIPs?

SIP panels come with wire chases already run in them. If access is needed somewhere off the standard pattern, the panels can be cut from the inside to allow wire and pipe installation, then reseal the openings with spray foam.

-

Fumigation

If there is one piece of advice we give to every barn buyer it is: DO NOT BUY A BARN FRAME THAT IS NOT PROPERLY FUMIGATED! If you do, you are looking for big trouble from some very little bugs, like powder post beetles. We fumigate all our barn frames before assembly.

It can be over twenty times more expensive to fumigate these stubborn pests when they are in your finished barn home and you need to move out of your house and have a fumigation company tent your entire house in order to fumigate it. We have licensed in-house fumigators on our staff and every one of our barns is thoroughly treated before it leaves our yard with a fumigant that has no residual effect.

Watch our video here!

-

Do You Need To Put A Finish On The Beams?

You can, but very rarely do people finish the beams. They have a deep, rich patina that has been acquired by years of exposure and they do not need a finish.

-

What Other Antique Materials Do You Have Available?

We have a large inventory of antique materials, including weathered barn siding, 2-inch thick threshing floor boards, and many other types of materials. We also have hand-hewn timbers, hand-forged iron hardware, barn doors, and more.

Testimonials

L. G. - Greenwhich, CT

M. & F. B. - Telluride, CO

M. M. - Barr Mansion Dutch Barn, Austin, TX

R. P. - Fairhope, AL

We recently had a wedding for 150 in the barn and people are still talking about the absolute beauty of the beams and frame and the "specialness" of being inside such a place. Keeping the authenticity of the original design and construction (for the most part) has made the barn "a place": of history, of fun and entertainment and a place just to be. We spend every night we are home in the barn so our main home is rapidly becoming our guest home! (:

Your team was amazing from our first discussion about "should we build a barn?" through the construction process. Steve, Tony and the rest of our architect/builder team feel as we do. How many times in a construction project do the team so significantly exceed expectations coming in on budget and ahead of schedule. And your team that we hosted at our home during the 'barn raising', couldn't have been more respectful, appreciative and fun.

We look forward to doing another one!

C. A. - Woodside, CA

B. W. - Fredericksburg, TX

A. F. - Selma Lake Retreat, Selma, AL

C. K. - Helotes, TX

B. & S .H. - Riverbend Barn Home, Medina, TX

G. W. - Stone Arabia Barn, Harper, TX